The Lindsey Lab:

Machine Learning & Simulation for Accelerated Materials Design & Discovery

Forging a Path from Edisonian to Intelligent Materials Design

Intelligent materials design and discovery necessitates detailed, atomistically-resolved understanding of the complex, often reaction-driven phenomena occurring over spatiotemporal scales spanning four orders of magnitude – information inaccessible through standard research approaches. Experimentally, short-timescale kinetic information is generally inaccessible, whereas computationally, models sufficiently accurate to describe complex chemical processes are generally unable to access the relevant scales. Consequently, much of materials design and discovery efforts are confined to highly inefficient Edisonian (i.e., trial-and-error) approaches.

In the Lindsey Lab, we develop and apply artificial intelligence (AI) -driven simulation and inference tools to bridge this capability gap and enable large scale “quantum” accurate simulations.

At the same time, we use these tools to:

1. Probe the fundamental question: How does chemistry govern material evolution and response under extreme temperature and pressure conditions?

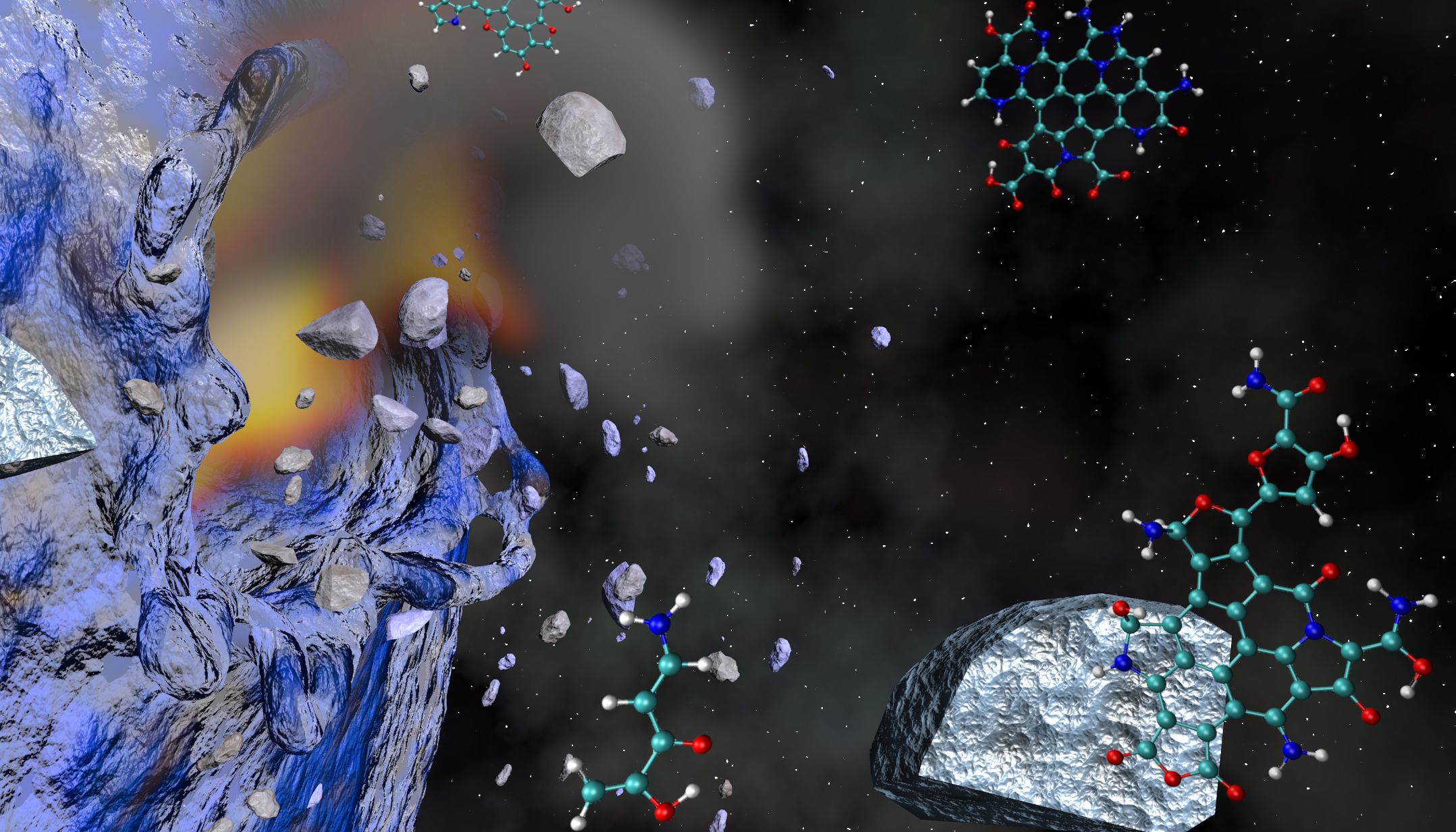

Extreme condition events wherein material is subject to 1000s of K and up to 100s GPa have been naturally occurring for millennia, e.g., within planetary interiors, lightening strikes, cometary impacts, and explosions. Nevertheless, we have limited understanding of precisely what, at the level of individual atoms, is going on within these events, due to significant challenges associated with creating and probing such conditions in a laboratory setting. Beyond providing an improved understanding of the world around us, these missing insights also have significant implications for, e.g., additive manufacturing, shockwave materials synthesis, and explosives design.

Therefore, we are deploying our AI-driven simulation capability in systematic studies building from single- to many-atom-type systems that ask the fundamental question: how does chemical composition govern the condensed-phase thermochemistry that ensues in these events? Read more about these efforts here: [1,2,3].

2. Exploit resulting insights for in silico design of next generation materials

Chemistry occurring under extreme temperature, pressure, and strain rate conditions has implications for a myriad of applications spanning advanced material processing techniques (e.g., laser ablation, sonication and electron-beam modification), defense applications (e.g., detonation science), sustainable energy (e.g., nuclear power), and beyond (e.g., geology, astrophysics, and astrobiology). Simulations can help us better understand the interplay between external stimuli (e.g., laser-drive) and precursor that ultimately govern resulting material characteristics – knowledge that can help improve efficiency and precision of these techniques. Our group combines AI-driven multiscale simulations and data science to facilitate advances in these areas. Read more about these efforts here: [1,2].

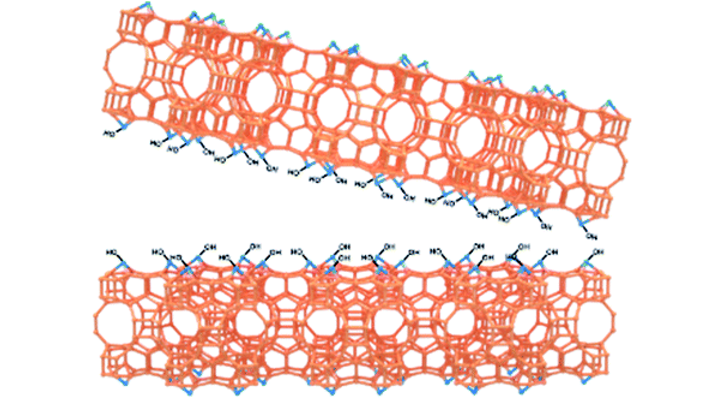

3. Establish an atomistically-resolved view of inherently multiscaled reacting systems1,2 to enable optimization of advanced synthesis and manufacturing technologies

Material and process optimization (e.g., for hydrogen storage, carbon sequestration, and catalysis) is frequently complicated by complex governing phenomena and massive design manifolds. We accelerate these efforts through atomistic simulation-informed machine learning strategies, i.e., using simulations to elucidate governing phenomena and identify regions of interest, and machine learning to identify optimal solutions within the resulting design spaces.

Questions we’re asking in this problem space include: What is the nucleation mechanism that drives solution-phase perovskite synthesis? How are halogens distributed in mixed-halide perovskites and how does that distribution impact performance? In zeolite membranes, why do nanosheet galleries provide such good selectivity for ammonia synthesis? Can we enhance performance by fine-tuning nanosheet complexing?